I’ve been thinking for a few days about the right approach: how can you safely enamel a brooch, for example, onto which a pin has been soldered?

Why it can go wrong

The question is: should you enamel first, or start by soldering the pin?

The physical parameters are as follows:

- Silver solder melts between 700 and 800°C, roughly speaking, depending on the type.

- Hot enamel melts at around 800°C (810°C for the WG Ball enamel I use).

There is therefore a certain probability that a soldered element may move when the jewelry is placed back in the oven for enameling.

The setup for an initial test

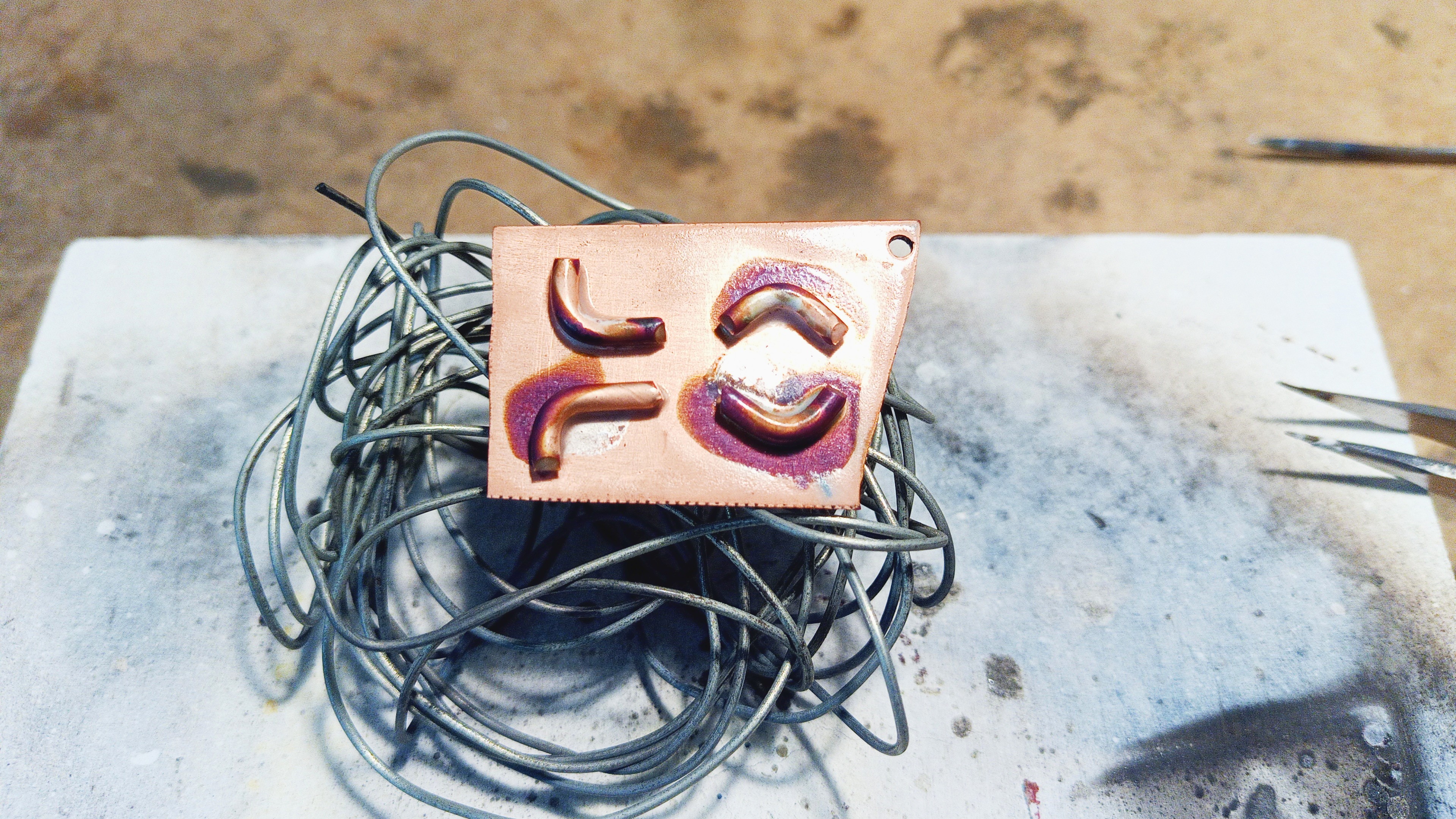

I prepared a small copper plate that I simply sanded (with 180 or 240 grit sandpaper), which will serve as a degreaser. This is sufficient for this small test.

I plan to attach some recycled copper wire to it, which I also simply sanded. Four curved pieces, to be attached flat.

This is an initial test, with the components securely in place.

Soldering

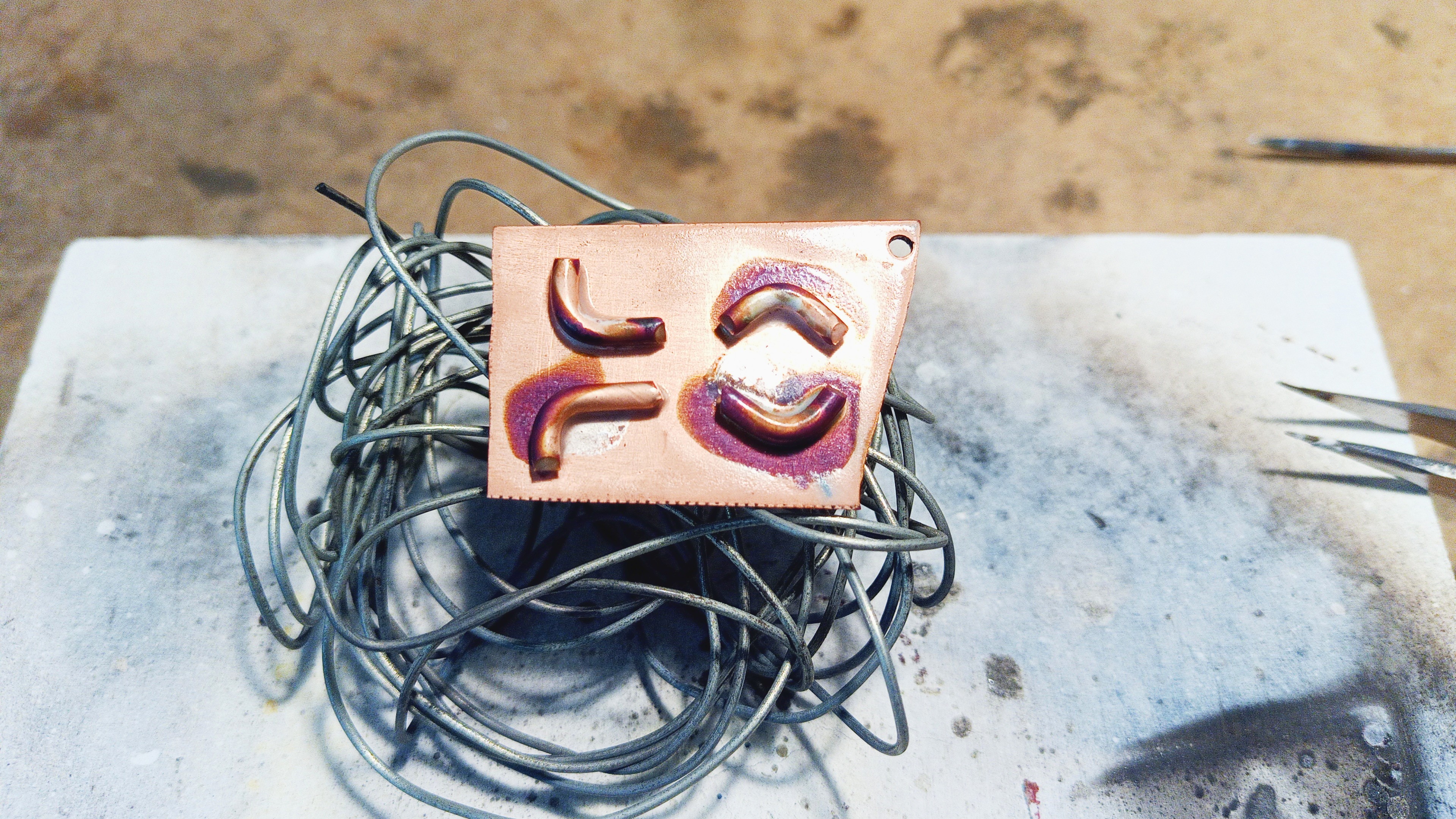

I will start by soldering two wires with low-temperature solder (melting range: 705-725°C) and two with high-temperature solder (melting range: 760-785°C). We will see if this makes a difference.

left: low-temperature solder; right: high-temperature solder

Enameling

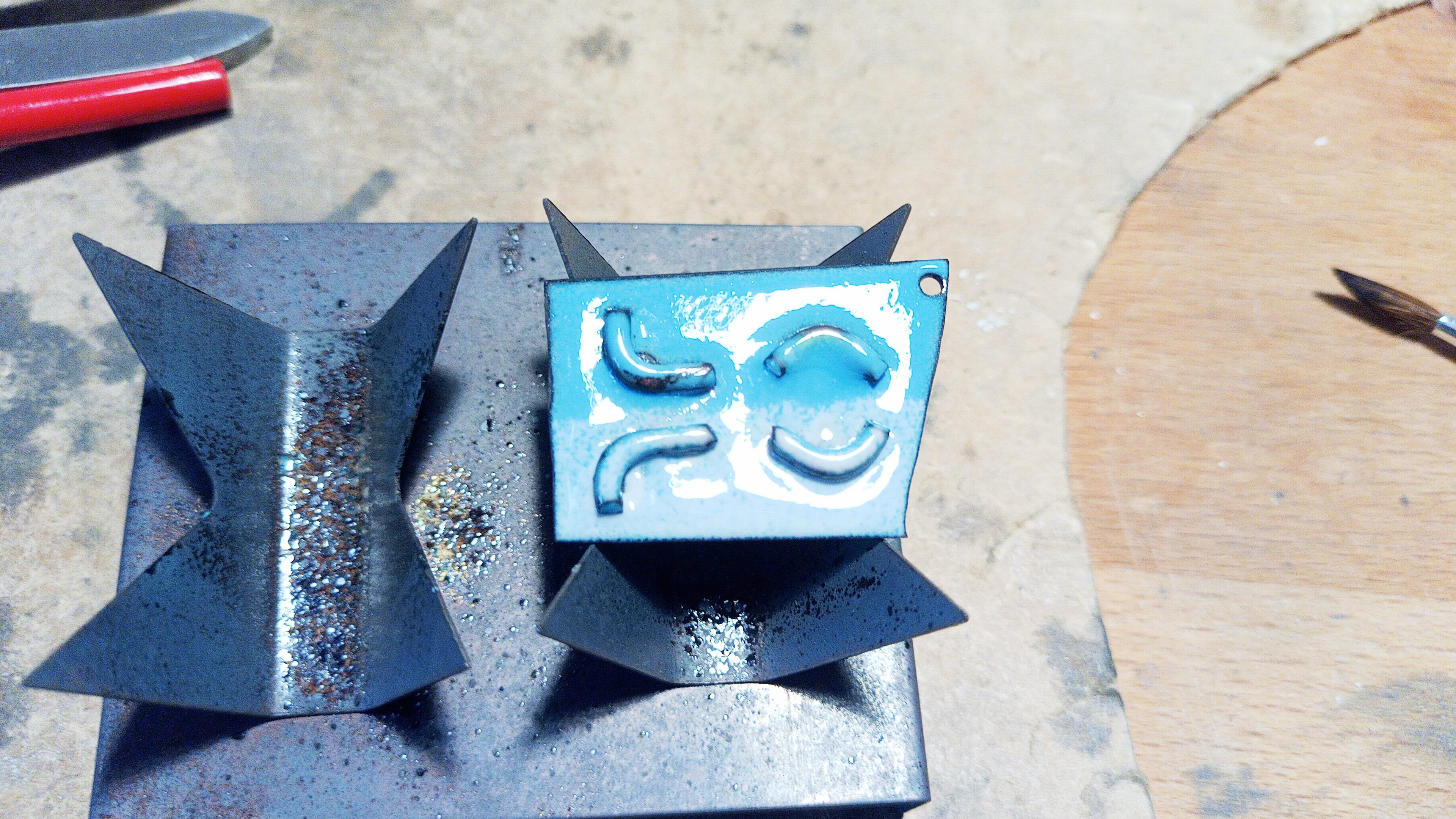

I then move on to enameling, using a counter-enamel.

The plate is enamelled in medium blue and pale gray

Is it strong?

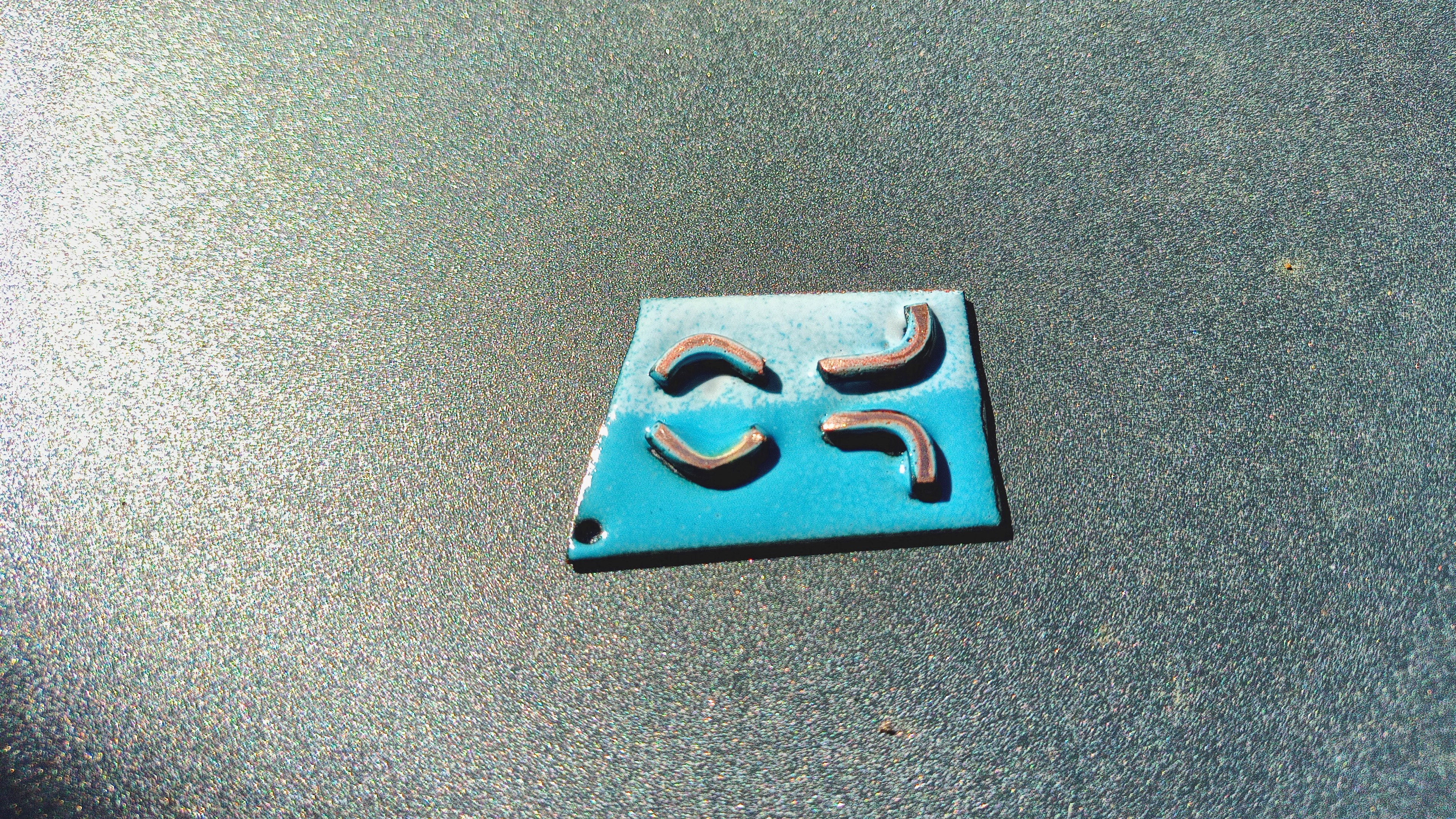

Next, I need to check whether the solder has been weakened. Let’s do a few tests.

- The assembly withstands several drops onto wood and tile.

- I then sand the copper wires with carborundum stone. It’s quite vigorous, but nothing moves.

The soldered wires are sanded with carborundum stone

Conclusion

In a configuration where the added elements are securely attached to the main plate, it appears that the solder (weak or strong) is not weakened by the subsequent enameling step. It will be necessary to confirm that this protocol is also reliable with a less stable assembly, such as a vertical nail.

In any case, it is likely that the viscosity of the molten enamel helps to keep the elements in place. What would happen if the soldered part were not covered by enamel? Next step!