Finishing steel, particularly in knife making, is a major challenge for beginners. On paper, it’s fairly straightforward, yet the first results are generally disappointing. Here are a few tips to help you avoid the frustration of a long job that ends up with a mediocre result.

Note that much of this advice also applies to metals in general…

Why sand steel?

As with wood, once the general shape of the object has been obtained, we try to improve the appearance of the steel. This could be a knife blade, for example, but it doesn’t matter: you want the surface to be even, pleasant to the touch, and why not polished to reflect your friendly face.

Tip 1: Take your time

It’s a bit obvious, but you can’t get a good result by rushing. That’s the difference between industry and craft. There are no machines to mass-produce perfect parts, no expensive R&D, no investors. But with a few good tools, know-how and time, you can produce unique pieces. That’s priceless. Philosophical considerations aside, we miss out on important details when we go too fast, and we learn less (I think).

Tip 2: Be rough

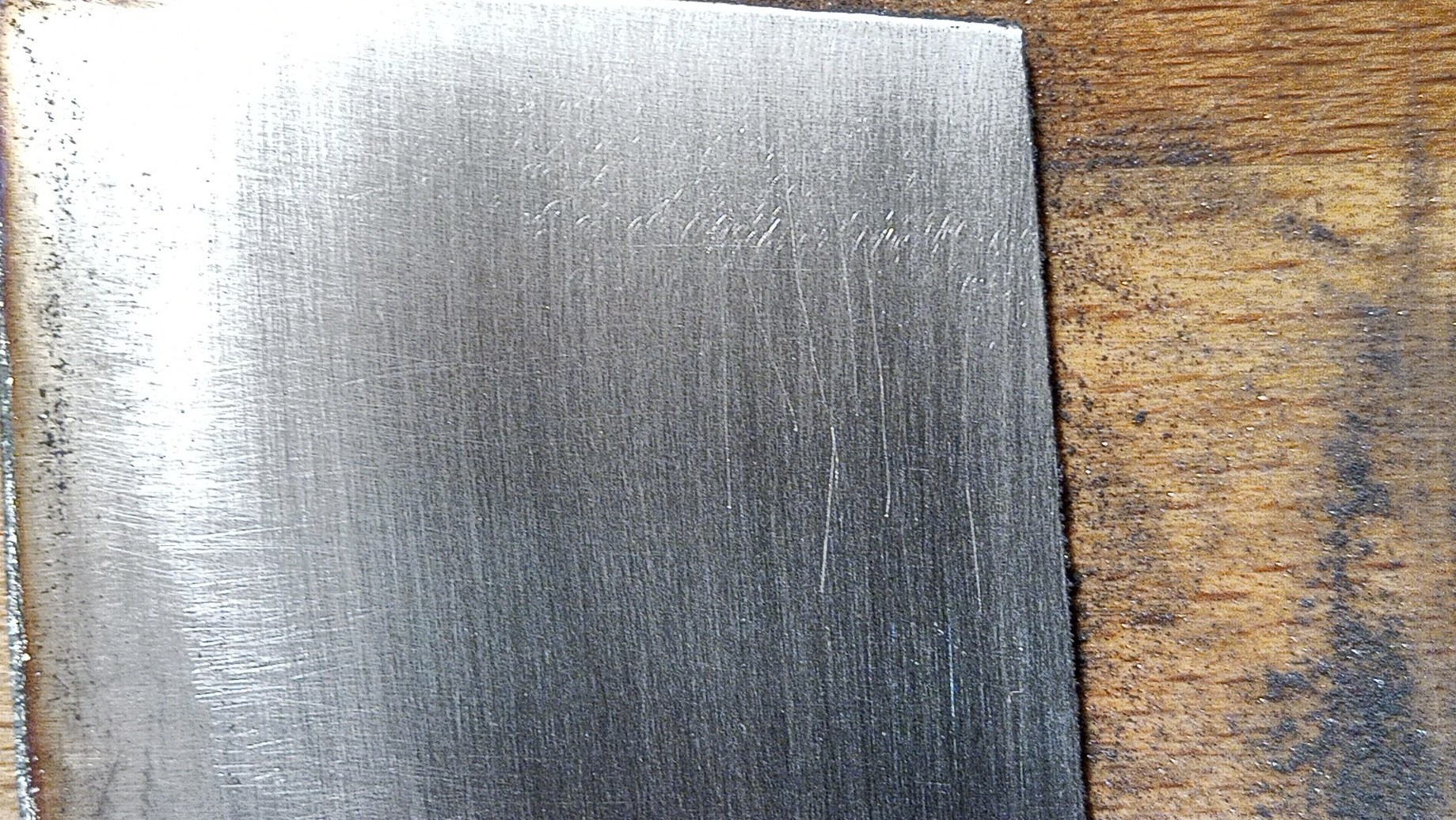

I don’t know if you’ll feel the same temptation as me, but when I started to tackle the finishing of a knife blade, I got it into my head that to get a ‘fine’ finish, I’d have to quickly switch to… fine sandpaper. This is a mistake, of course. When you sand metal, the first thing you want to do is eliminate the deepest scratches. And that takes a long time! Once the surface has been evened out, even roughly, you can gradually refine the grains, which requires some effort, but it’s almost a formality if the preliminary work has been serious. As far as I’m concerned, I go after the big defects with 120 grit, which seems to me to be a good balance between efficiency and regularity of sanding.

Roughing out, it’s important.

Tip 3: Release the pressure

Especially before changing grit! This will prevent you from scratching the surface deeply in places just before moving on to the next grit - which is inherently less effective. So sand firmly, regularly, but without forcing yourself. Change your abrasive paper regularly, especially fine abrasives, which wear out very quickly.

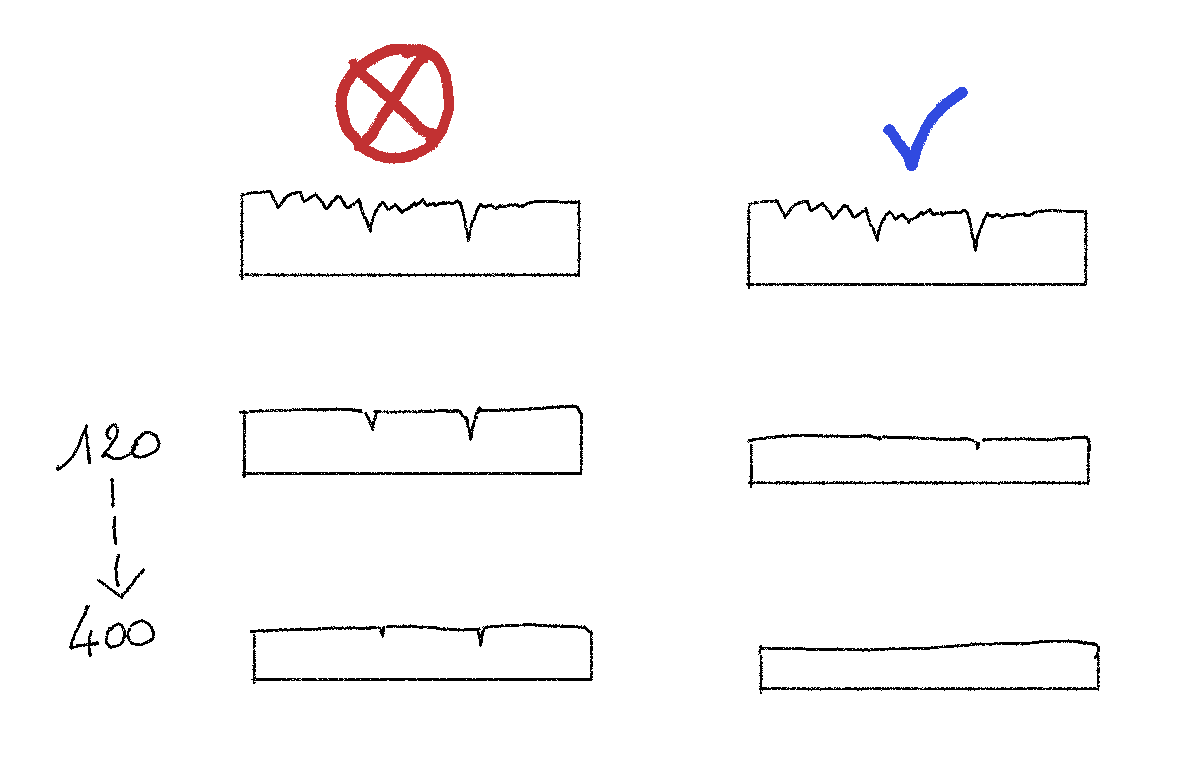

Tip 4: Cross the grains

It’s not necessarily easy with a backstand but when you sand by hand, feel free to alternate the direction of sanding from one grit to the next. This is a good way of revealing scratches that were ‘forgotten’ in the previous grit. If there are a lot of scratches or deep scratches, and they don’t go away quickly enough : go back to the previous grain until you see some progress.

Sanding always in the same direction masks deep scratches

Cross-sanding reveals deep scratches more clearly

Tip 5: Make yourself comfortable!

You’re going to spend a lot of time sanding, re-sanding, correcting and getting (a bit) worked up. To avoid injury and keep your back straight, take the time to settle in properly and take care of your joints.

I use a good stool and a really solid, practical precision vice: the Proxxon FMZ (around 50€).

Good luck!